Why Your 4 Stroke Cooling System Matters More Than You Think

A 4 stroke cooling system is the unsung hero keeping your engine alive. Whether you’re powering a boat, ATV, or other recreational vehicle, this system prevents catastrophic damage by managing extreme heat from combustion.

Quick Answer for “4 Stroke Cooling System”:

- Primary Function: Remove excess heat to prevent engine damage while maintaining optimal operating temperature (around 200°F/93°C)

- Two Main Types: Air-cooled (simpler, lighter, uses fins and airflow) and liquid-cooled (more efficient, uses coolant circulation)

- Key Components: Thermostat, water pump, radiator/heat exchanger, coolant passages, hoses, pressure cap

- Common Issues: Overheating from clogged passages, failed thermostat, worn impeller, low coolant, or leaks

- Essential Maintenance: Check coolant levels, inspect hoses, replace impeller regularly, flush system periodically

Combustion inside your engine reaches temperatures around 4,500°F (2,500°C). Only about 25% of that energy becomes mechanical power; the rest is pure heat. Without proper cooling, pistons can weld themselves to cylinder walls and engine blocks can crack. The cooling system on a car driving down the freeway dissipates enough heat to heat two average-sized houses.

Beyond preventing meltdowns, your cooling system helps the engine warm up quickly, reduces wear, cuts emissions, and maintains consistent performance.

I’m mArk saToshi, and at Anqi E-Bikes, I’ve seen how 4 stroke cooling system failures sideline excellent equipment. Understanding these systems transforms owners from reactive repairers into proactive maintainers.

The Heart of Heat Management: Why Cooling is Critical

Your engine is a controlled explosion chamber, with combustion temperatures reaching 4,500°F (2,500°C). The 4 stroke cooling system exists to manage this inferno and keep your engine at its optimal operating temperature—not just “cool.”

While preventing overheating is critical to avoid seized pistons and cracked engine blocks, the system is equally important for helping the engine warm up quickly. A cold engine is inefficient. When components haven’t reached their ideal temperature (typically around 200°F or 93°C), several problems emerge:

- Engine efficiency suffers. Cold parts wear faster, fuel doesn’t vaporize completely, and you burn more fuel for less power.

- Engine longevity decreases. Both excessive heat and running too cool cause thermal stress, component warping, and carbon buildup. Proper temperature regulation extends the life of your investment.

- Emissions increase. An engine at optimal temperature achieves more complete combustion, reducing the pollutants that exit your exhaust.

Think of your 4 stroke cooling system as a temperature manager. It’s the guardian that prevents damage while ensuring peak performance. Without it, even the finest engine becomes expensive scrap metal.

For a deeper understanding of these principles, check out how an engine cooling system works.

The Two Titans of Temperature Control: Air vs. Liquid Cooling in Outboards

Not all 4 stroke cooling systems are created equal. In outboard motors, you’ll find two main approaches: air-cooling and liquid-cooling. Each has its place on the water.

The Simplicity of Air-Cooling

Air-cooled engines work on a simple principle: moving air removes heat. The cooling fins cast onto the engine block and cylinder head dramatically increase the surface area for heat to escape via convection. Airflow comes from the boat’s speed or a dedicated fan, often guided by shrouds and baffles to direct it where it’s needed most.

The appeal of air-cooling is that it’s lighter (no coolant, pump, or radiator) and simpler, with fewer parts to fail. Our 7.5 HP outboard model, for example, uses an air-cooling system with multiple exhaust vents to reduce temperature. The XP200A(-3) engine—a 4-stroke, air-cooled single cylinder with 196cc displacement—shows how effective this is for smaller applications.

The trade-off is less consistency. On hot days or during long, high-throttle runs, they may not maintain temperature as precisely. They also tend to be noisier due to less insulation.

The Power of Liquid-Cooling

Liquid-cooled systems dominate modern, high-horsepower outboards because they are more effective. A water pump circulates coolant (a water/antifreeze mix) through water jackets in the engine block, absorbing heat directly. The heated coolant then travels to a heat exchanger, where it transfers heat to the surrounding lake or ocean water before returning to the engine.

This is typically a closed-loop system, so internal coolant doesn’t mix with the external water. Some designs use a hybrid approach, combining a closed loop for the engine with an open loop that uses external water to cool the exhaust.

The advantages are higher efficiency, quieter operation, and solid temperature control. Our ATV-Automatic 1000cc 4×4, with its liquid-cooled V-Twin cylinder engine, demonstrates the power this cooling approach can support. The same principles apply to large outboard motors.

Head-to-Head: Air-Cooled vs. Liquid-Cooled Outboards

Which 4 stroke cooling system is right for your outboard? It depends on your needs.

| Feature | Air-Cooling | Liquid-Cooling |

|---|---|---|

| Complexity | Simpler, fewer moving parts | More complex, requires multiple components |

| Weight | Lighter (no coolant, radiator, water pump) | Heavier (adds coolant, radiator, pump, hoses) |

| Maintenance | Less frequent, mainly cleaning fins | More involved (coolant checks, flushes, impeller) |

| Cooling Efficiency | Good for smaller engines, less consistent | Excellent, highly consistent temperature control |

| Cost | Generally lower manufacturing and repair costs | Higher initial and potential repair costs |

| Typical Applications | Small outboards, generators, some e-bikes, older engines | Modern outboards, ATVs, cars, high-performance engines |

Air-cooling shines in smaller outboards where simplicity and weight are priorities. Liquid-cooling is necessary for consistent power, quieter operation, and larger engines that generate serious heat. Neither is “better” in absolute terms; they are suited to different roles.

Anatomy of a Liquid-Cooled 4 Stroke Outboard Cooling System

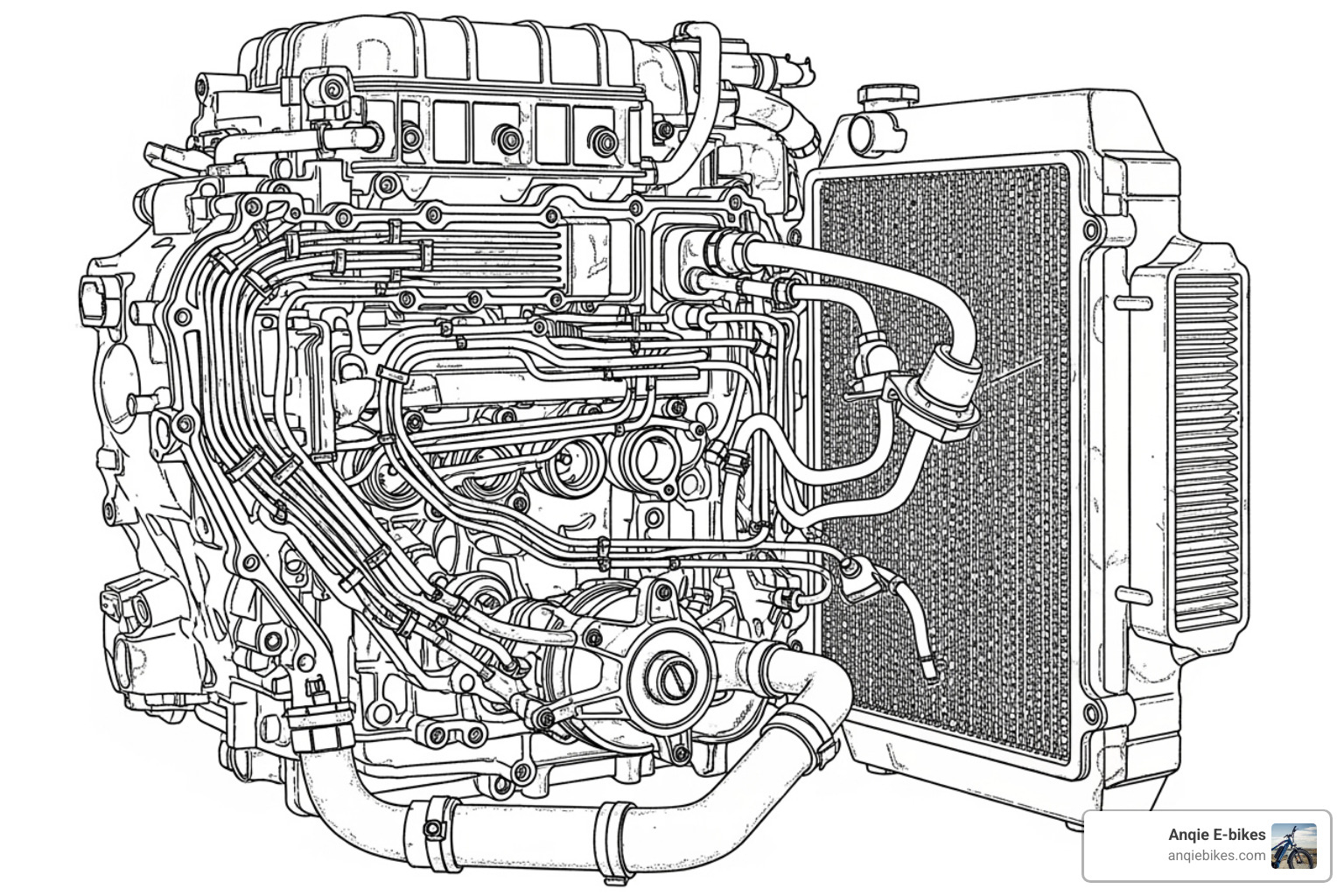

Now that we understand why liquid-cooling is the go-to choice for modern outboards, let’s pop the hood (so to speak) and explore what’s actually happening inside your 4 stroke cooling system. Think of it as a carefully choreographed dance where every component has to perform perfectly, or the whole show falls apart.

The Regulator: How the Thermostat Controls Temperature

Picture this: you’re trying to keep your morning coffee at the perfect drinking temperature while the weather outside swings from freezing to sweltering. Sounds impossible, right? Yet that’s essentially what your thermostat does for your engine—maintaining that sweet spot around 200°F (93°C) no matter what’s happening around you.

Here’s the clever part. When you first fire up your engine on a cold morning, the thermostat stays completely closed. No coolant flows to the radiator at all. This might sound counterintuitive, but it’s actually brilliant—your engine needs to warm up quickly for optimal efficiency. Running cold causes all sorts of problems: increased wear, sluggish performance, higher emissions, and poor fuel economy.

Inside that little thermostat housing sits a wax pellet that responds to temperature changes. As your coolant heats up, this wax expands and pushes against a rod, which gradually opens a valve. Once the coolant reaches the thermostat’s rated temperature (typically around 180°F to 195°F), the valve opens fully, allowing hot coolant to flow out to the radiator where it can be cooled.

The beauty of this system is its automatic nature. Idling at the dock? The thermostat keeps things just right. Suddenly throttle up to full power? The thermostat responds instantly, opening wider to handle the increased heat. It’s constantly adjusting to keep your engine in that optimal temperature range where everything—fuel vaporization, oil viscosity, metal tolerances—works exactly as designed. For a fascinating look at how this ingenious device works, check out How a car’s thermostat works.

The Circulator: The Water Pump’s Crucial Role

If the thermostat is your system’s brain, the water pump is definitely its heart—constantly pumping, never resting, moving coolant through your entire 4 stroke cooling system. We’re talking about circulating hundreds or even thousands of gallons per hour!

In an outboard motor, the water pump typically sits in the lower unit, right where it can do its job efficiently. The real workhorse here is the impeller—a small component with flexible rubber or plastic vanes that spins rapidly to create flow. As it rotates (driven by your engine’s driveshaft), it pulls coolant in and pushes it through the system under pressure.

Here’s where things get interesting for outboard owners. Many outboards use what’s called an open-loop system, where the pump draws fresh water directly from the lake or ocean. This water cools either the engine directly or a heat exchanger that cools the internal coolant. You can actually see this system working! That little stream of water shooting out of the “pee-hole” or tell-tale outlet? That’s your visual confirmation that your impeller is doing its job.

No stream? That’s trouble. A weak or absent tell-tale stream usually means your impeller has worn out, or something’s blocking the water intake. The rubber vanes on impellers can crack, break, or wear down over time, especially if you’ve accidentally run the engine out of water (even briefly). This is why experienced boaters check their tell-tale stream regularly and replace their impellers every few years, depending on usage. It’s cheap insurance against a catastrophically overheated engine. For more detailed information on marine cooling systems, visit Understanding Outboard Motor Cooling Systems.

The Heat Exchanger: Water Jackets, Hoses, and Pressure

Now let’s talk about where the actual cooling happens. Your engine block and cylinder head are riddled with passages called water jackets—channels cast right into the metal that allow coolant to flow around the hottest parts of your engine. This is where the coolant absorbs all that excess combustion heat.

The heated coolant then travels through hoses to your radiator or heat exchanger. In marine applications, a heat exchanger works similarly to a car radiator but uses the surrounding water instead of air. These heat exchangers are essentially networks of small tubes surrounded by fins, all designed to maximize surface area. Hot coolant flows through the tubes while cooler external water flows around them, transferring heat away efficiently. Modern designs even include turbulators inside the tubes—little twisted fins that create turbulence in the coolant flow, which dramatically improves heat transfer.

The hoses connecting everything might seem like simple plumbing, but they’re actually engineered to handle some serious abuse. They need to stay flexible while withstanding high temperatures (often exceeding 200°F) and significant pressure without bursting or collapsing.

Speaking of pressure, here’s something many people don’t realize: that pressure cap on your system isn’t just keeping coolant from sloshing out. It’s actually raising the boiling point of your coolant! Here’s how it works: for every pound per square inch (psi) of pressure, water’s boiling point increases by about 3°F. A typical system running at 14-15 psi raises the boiling point by roughly 45°F, meaning your coolant won’t boil until it reaches around 257°F instead of 212°F.

The pressure cap also has a vacuum valve that opens when the system cools down and contracts, allowing air back in so your hoses don’t collapse. It’s a small component, but if it fails, your coolant could boil and overflow even when your engine temperature is perfectly normal. That’s why checking your pressure cap should be part of your regular maintenance routine for your 4 stroke cooling system.

Keeping Your Cool: Common Issues and Maintenance Fixes

Even the most robust 4 stroke cooling system can encounter issues. The good news? Most problems are preventable with a bit of attention. Your cooling system works hard to protect your engine, so it deserves some TLC in return. Let’s walk through how to spot trouble early and keep everything running smoothly.

Diagnosing Overheating in Your 4 Stroke Outboard Cooling System

Overheating is your cooling system’s way of waving a red flag. Your temperature gauge or warning lights are your first alert. If the needle climbs into the danger zone or a warning light comes on, don’t ignore it! Head to shore if you’re on the water.

Steam billowing from your engine is another unmistakable sign that your coolant is boiling. You might also notice your coolant level is mysteriously low, which could point to a leak.

What causes these episodes? A thermostat failure is a common culprit. If it gets stuck closed, coolant can’t reach the radiator to cool down. Clogged water passages are another frequent troublemaker, especially in marine environments where rust, scale, or salt crystals can build up and choke off flow.

Don’t forget about leaks. Hoses crack with age, clamps loosen, and water pumps can develop seal failures, all of which let coolant escape.

For outboard motors specifically, watch for impeller malfunction. If you’re not seeing a strong, steady stream of water from the tell-tale outlet (the “pee-hole”), your impeller is likely worn, damaged, or the intake is blocked. This is one of the most common outboard cooling issues, and catching it early can save your engine.

Essential Maintenance for Your 4 Stroke Outboard Cooling System

Proactive maintenance is infinitely better than dealing with a seized engine. These habits will keep your system healthy:

Check your coolant level regularly. When the engine is cold, verify that your coolant reservoir is at the proper mark. This simple check can alert you to slow leaks.

Every few years, perform a coolant flush according to your manufacturer’s schedule. Coolant breaks down over time and picks up contaminants. A flush clears out this junk and replaces it with fresh, protective coolant.

Always maintain a 50/50 antifreeze mix (50% antifreeze, 50% distilled water). This ratio prevents freezing, raises the boiling point, and delivers corrosion inhibitors that protect your engine’s internal metal components.

Inspect your hoses periodically. Squeeze them when cool. If you find cracks, bulges, or hard/soft spots, it’s time to replace them.

For outboard owners, flushing your water passages after every saltwater outing is essential to prevent salt buildup. Learn more about this at Understanding Outboard Motor Cooling Systems.

Finally, make water pump impeller replacement part of your regular maintenance. Most manufacturers recommend replacement every 100-300 hours or 2-3 years. This small part does enormous work, and replacing it proactively is cheap insurance against an overheated engine.

Frequently Asked Questions about 4-Stroke Outboard Cooling

We hear from customers all the time—whether they’re out in Brooklyn, NY, or cruising somewhere halfway across the country—with great questions about their 4 stroke cooling systems. Let’s tackle the ones that come up most often.

What’s the ideal operating temperature for a 4-stroke outboard engine?

Your engine is happiest when it’s running at around 200 degrees Fahrenheit (93 degrees Celsius). I know that sounds hot, but there’s real science behind this sweet spot.

At this temperature, fuel vaporizes completely, which means you get efficient combustion and the power you paid for. Your engine oil also hits its optimal viscosity—not too thick like cold syrup, not too thin like hot water. This ensures all those moving parts get the lubrication they need without excess friction.

There’s more: at 200°F, metal components have expanded to their correct tolerances. This might sound technical, but it basically means everything fits together exactly as the engineers intended, reducing wear and tear. And as a bonus, more complete combustion at this temperature means fewer nasty emissions coming out the back.

So when your temperature gauge hovers around 200°F, that’s not a problem—that’s your engine running exactly as it should.

Can I just use pure water instead of coolant in my liquid-cooled outboard engine?

Short answer? No, don’t do it. I get why you’d ask—water is cheap, readily available, and it does conduct heat well. But here’s the problem: water alone just can’t handle what your 4 stroke cooling system throws at it.

Pure water freezes at 32°F (0°C). If that happens inside your engine, the expanding ice can crack your engine block or radiator. That’s not a “quick fix” situation—that’s a “replace the entire engine” situation.

On the flip side, water boils at 212°F (100°C), and your engine regularly operates above that temperature, especially when you’re pushing it hard. Boiling water means steam, pressure buildup, and rapid overheating.

But here’s what really gets me: pure water is corrosive. Without the anti-corrosion additives found in proper antifreeze (ethylene glycol), you’re inviting rust and electrolysis to slowly eat away at the aluminum and other metals in your engine. Those additives also lubricate your water pump, extending its life.

A 50/50 mixture of antifreeze and distilled water is the standard for good reason. It raises the boiling point to around 223°F, lowers the freezing point to about -35°F, and protects your engine’s internal components from corrosion. It’s not just about temperature—it’s about protecting your investment.

What are the signs of a failing water pump or impeller?

For outboard motor owners, this is crucial: the number one sign of impeller trouble is a weak or non-existent stream of water from the tell-tale outlet—that little “pee-hole” that shoots water while your engine runs. If that stream is weak, intermittent, or completely absent, your impeller is likely worn out or damaged, and your engine isn’t getting the cooling it needs.

Beyond that tell-tale sign (pun intended), watch for your engine consistently overheating. If your temperature gauge keeps climbing into the red or your overheat alarm keeps sounding, your water pump might not be circulating coolant properly.

Sometimes you’ll hear a whining or grinding noise coming from the pump area—that’s often a bearing going bad. And if you spot visible coolant leaks around the water pump housing, that indicates a seal failure.

If you notice any of these symptoms, especially that weak tell-tale stream, don’t ignore it. Address it immediately. A worn impeller is a relatively inexpensive fix. A seized engine from overheating? That’s a whole different conversation—and a much more expensive one.

Conclusion

Your 4 stroke cooling system is far more than just another engine component—it’s the guardian standing between smooth operation and catastrophic failure. Whether you’re drawn to the straightforward simplicity of air-cooling or the precise temperature control of liquid-cooling, understanding how your system works transforms you from a casual owner into a confident caretaker.

Think about it: every time you fire up that outboard motor for a weekend fishing trip, or throttle your ATV through challenging terrain, or cruise peacefully on your e-bike, your cooling system is working tirelessly behind the scenes. It’s maintaining that perfect 200°F sweet spot, protecting pistons from seizing, preventing engine blocks from cracking, and ensuring you get years of reliable performance from your investment.

The difference between an engine that lasts a decade and one that fails prematurely often comes down to simple, regular maintenance. Checking coolant levels takes two minutes. Flushing your outboard after saltwater use takes five. Replacing an impeller before it fails costs a fraction of what you’d pay for a seized engine. These small acts of care compound over time, giving you peace of mind and keeping you on the water, trail, or road where you belong.

Here at Anqie E-bikes in Brooklyn, NY, we’ve seen how proper cooling system maintenance separates the happy long-term owners from those dealing with preventable breakdowns. That’s why our team doesn’t just sell you quality e-bikes, dirt bikes, and outboard motors—we’re here to guide you through ownership with expert advice and genuine support. We want your equipment running strong for years to come.

Ready to explore your options or need advice on maintaining your current setup? Explore our range of 4-stroke outboard motors and connect with our knowledgeable team. We’re always happy to answer your questions, share maintenance tips, or help you find the perfect equipment for your next adventure. Stay cool out there, and enjoy every ride!